What Are Thermal Interface Materials and Why Does It Matter

In today’s powerful electronics, keeping devices cool is more important.Thermal Interface Materials (TIMs) help by moving heat from components like CPUs, GPUs, and power chips to cooling systems such as heat sinks. Without TIMs, devices can overheat, slowing performance or causing damage. This article explains TIMs and how they help keep electronics cool, stable, and efficient.

What Are Thermal Interface Materials (TIMs)?

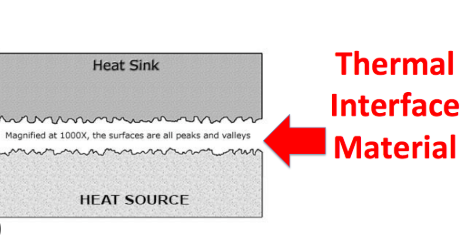

TIMs are materials placed between two surfaces to improve heat transfer, keeping electronic components cool and operating efficiently. They fill tiny gaps, bumps, and air pockets that would normally block heat, allowing it to flow smoothly from one component to another.

Why Use TIMs?

- Enhance Heat Transfer: Improve heat flow by filling tiny gaps, helping heat move efficiently from electronic parts to their cooling devices.

- Prevent Overheating: Keep temperatures low to avoid performance issues or damage.

- Improve Reliability: Proper cooling helps electronics last longer and work more reliably.

Where Are TIMs Used?

TIMs are commonly applied between heat-generating parts and devices that dissipate heat:

- Heat-Generating Components:

- CPUs (Central Processing Units).

- GPUs (Graphics Processing Units).

- Power ICs (Integrated Circuits).

- Heat-Dissipating Devices:

- Heat sinks.

- Heat spreaders.

- Vapor chambers.

- Chassis.

By ensuring efficient heat transfer, TIMs help maintain safe operating temperatures and extend the life of electronic devices.

How Thermal Interface Materials Work

TIMs transfer heat from hot electronic components to cooling structures, helping keep devices safe and efficient.

- Filling Tiny Gaps

TIMs fill microscopic gaps on surfaces to improve contact and enhance heat transfer.

- Conducting Heat Efficiently

TIMs are made to transfer heat well. Silicone-based pads may reach thermal conductivities around 25 W/m·K, while advanced graphene-enhanced TIMs can exceed 1800 W/m·K.

- Maintaining Pressure for Full Contact

TIMs require pressure to fully touch both surfaces, filling all gaps and ensuring optimal performance.

- Handling Thermal Expansion

Electronic components expand and contract with heat. TIMs are designed to flex with these changes, preventing stress or damage.

- Improving System Reliability

TIMs efficiently transfer heat and reduce thermal resistance, keeping devices cool, boosting performance, and extending their lifespan.

TIMs help prevent overheating, enhance reliability, and prolong the lifespan of electronic devices.

Types of Thermal Interface Materials

TIMs are materials used in electronics to carry heat away from hot parts like CPUs, GPUs, or power chips to cooling devices like heat sinks. They improve heat flow and prevent overheating.

- Thermal Pads

Pre-formed solid sheets made of thermally conductive material.

- Features: Flexible, available in different hardness levels to match surface irregularities.

- Uses: Ideal for uneven surfaces, like GPUs and power ICs.

- Thermal Tape

Double-sided adhesive tape with thermal fillers.

- Features: High thermal conductivity, strong adhesion, low thermal resistance.

- Uses: Attaching heat sinks while providing thermal transfer and mechanical bonding.

- Thermal Paste (Thermal Grease)

Thick compounds that fill microscopic gaps.

- Features: Moves heat well and is available in either silicone or non-silicone types.

- Uses: Commonly used between CPUs/GPUs and heat sinks.

- Thermal Putty

Soft, moldable material.

- Features: Can fill larger gaps; high thermal conductivity.

- Uses: Filling bigger gaps or voids in thermal interfaces.

- Phase Change Materials (PCMs)

Materials that melt at certain temperatures.

- Features: Solid at room temperature, liquid when heated to fill gaps.

- Uses: Thermal interfaces that need to adapt to temperature changes.

- Thermal Conductive Gel

Gel-like material.

- Features: Flexible, conforms to complex surfaces.

- Uses: Applications needing both heat transfer and cushioning.

- Potting Compounds

Materials used to encapsulate components.

- Features: Thermally conductive, protects against moisture and stress.

- Uses: Protecting sensitive components while providing heat transfer.

- Graphite Sheets

Thin, flexible graphite sheets.

- Features: High thermal conductivity, spreads heat over large areas.

- Uses: Efficient heat dissipation for large surfaces.

- Graphene

Single-atom-thick carbon layers.

- Features: Exceptional thermal conductivity and strength.

- Uses: High-performance electronics.

- Thermal Composite Materials

Combinations of materials for improved thermal and structural performance.

- Features: Customized properties for specific needs.

- Uses: High-end applications requiring both thermal efficiency and mechanical strength.

Selecting the right TIM helps keep your device cool and makes it last longer.

Key Properties of Thermal Interface Materials

Thermal Interface Materials (TIMs) are essential for transferring heat efficiently from electronic components to heat sinks. Their effectiveness depends on several key properties:

- Thermal Conductivity (W/m·K)

This shows how well a material carries heat. Higher values mean heat moves more easily. Metals like copper are very good at this, but TIMs usually conduct less heat. They still work well by filling tiny gaps and matching the surfaces to help heat flow efficiently.

- Electrical Insulation vs. Conductivity

- Insulating TIMs: Prevent electrical shorts, which are important for sensitive electronics.

- Conductive TIMs: Transfer heat and conduct electricity, used in specialized applications.

- Operating Temperature Range

A TIM must remain stable under different temperatures. High-quality TIMs can handle temperatures of 150°C or higher, ensuring reliable performance in demanding conditions.

- Viscosity, Thickness, and Compressibility

- Viscosity: Determines how easily the TIM spreads and fills gaps.

- Thickness: Too thick can increase resistance; a balance is needed.

- Compressibility: Allows TIMs to fill surface gaps, enhancing contact and heat transfer.

- Long-Term Reliability (Pump-Out & Dry-Out)

Some TIMs may move or dry out, reducing their ability to transfer heat. High-quality TIMs resist these issues, ensuring consistent cooling and reliable device performance.

Understanding these properties helps select the right TIM for your application, ensuring efficient heat management and longer-lasting electronic components.

Why Thermal Interface Materials (TIMs) Matter in Electronics

TIMs are materials that fill tiny gaps between hot components and cooling parts, helping heat flow efficiently and keeping electronics cool.

Why They Matter

- Prevent Overheating: Enhance heat transfer to avoid electronic failure.

- Stop Thermal Throttling & Shutdowns: Keep temperatures safe to prevent slowdowns or shutdowns under heavy use.

- Ensure Stable Performance: Maintain consistent temperatures for reliable operation.

- Handle Heavy Loads: Enable demanding tasks without overheating.

- Extend Component Lifespan: Minimize thermal stress to slow wear and degradation, ensuring longer, more reliable operation.

- Enable Compact Designs: TIMs enable compact designs by efficiently managing heat, allowing slim, high-powered devices to operate safely.

TIMs are a hidden but critical part of electronics, enabling cooler, faster, and longer-lasting performance in today’s compact, high-performance devices.

Challenges and Best Practices in Thermal Interface Materials

TIMs remove heat from electronics, helping smaller, more powerful devices stay cool, work well, and last longer. Here are the challenges of TIMs:

- High Thermal Resistance at Interfaces

Even if a TIM conducts heat well, the interface between the TIM and the component can resist heat flow. This can create hotspots, especially in high-power devices, reducing efficiency.

- Mechanical Instability

TIMs must maintain surface contact despite repeated heating and cooling. Materials like thermal paste can shift, dry out, or degrade over time due to differing expansion rates of device components.

- Environmental Degradation

High temperatures can cause TIMs to oxidize, release gases, or dry out, reducing their effectiveness and leading to premature failure.

- Filler Alignment in Polymers

Adding materials like graphene or boron nitride can improve thermal conductivity. But if these fillers aren’t aligned properly in the TIM, performance suffers.

- Compatibility with Different Components

Modern devices have components with different cooling needs. A good TIM must handle varying heat loads without reducing overall performance.